If you’ve ever wondered how those stunning pieces of crystal that companies like Waterford Crystal are famous for, then a tour behind the scenes of the Waterford Crystal factory is a must-do in Ireland. The tour takes you up close to each step in the manufacture of these works of art, from molten glass to the finished and polished crystal masterpiece.

Want to save this for later? Click the Pinterest button on the left for a pinnable image!

This post may contain affiliate links. Please read our full disclosure policy here.

Waterford Crystal was started in the late 18th century by George and William Penrose when they were granted aid by Parliament to start the manufacture of flint glass. Within a year they had the factory up and running producing many different pieces from their staff of 50-70 of the best craftsmen, blowers, cutters, and engravers. Being more businessmen than glass specialists they brought on board a man named John Hill who knew the best secrets to mixing glass materials and suggested polishing the glass after cutting to remove the “frosted” look, which has since become one Waterford’s signatures of clarity and purity. For almost 70 years Waterford flourished before disastrous economic conditions in 1851 forced its closure.

After 100 years the story of Waterford Crystal resumes. A glassmaker named Kael Bacik hired Miroslav Havel as Chief Designer and together they brought Waterford Crystal back to life. They studied examples of the Penrose brothers’ crystal and their traditional cutting patterns became the design basis for the new company. Havel created the now-iconic “Lismore”, which remains the world’s best-selling crystal pattern.

But it wasn’t all clear sailing for Waterford even then. In the late 1980s and early 1990s, Waterford Crystal was again hit with a major financial crisis due to the fall in the value of the dollar, decline in demand, and some costly restructuring attempts. Fortunately, some new investors stepped in to help keep it going. On New Year’s Eve 2000, Waterford Crystal in the spotlight and seen by an estimated 1.2 billion people as their crystal ball was lowered in Times Square, New York City to ring in the new millennium. Unfortunately, by 2009 it was announced that Waterford Crystal was having issues again and was in receivership but again, help arrived when a US-based firm stepped in and had the funds to keep it going.

In 2010 the Waterford Crystal Manufacturing Facility was opened and since then more than 800,000 people have visited the store and factory tour to see how the new factory maintains very strong ties with its predecessors, especially with their dedication to purity, design, and quality. If a piece is not perfect it is broken, melted down, and started again. It is as simple as that.

HIGHLIGHTS OF THE WATERFORD CRYSTAL TOUR

Tours of Waterford Crystal are fully guided. Your guide will escort you through the various parts of the factory and explain the process of each stage as you watch the expert craftsmen perform each of their meticulous tasks in front of your eyes.

INTRODUCTION

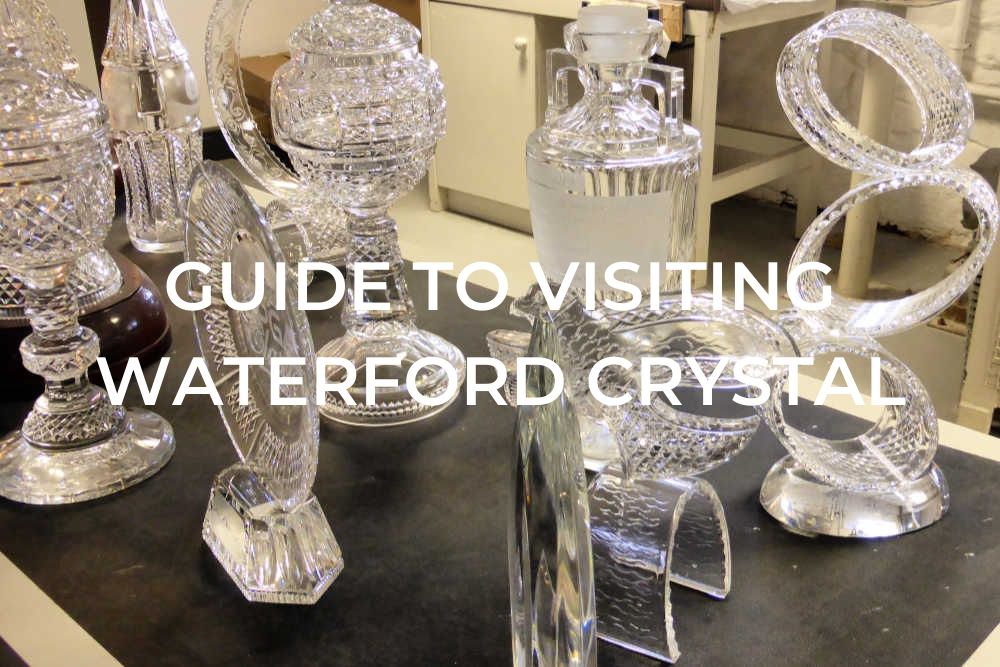

You start in a room where your guide gives you a history of the company and you can see many different pieces from over the years to show how some of the designs evolved. There is also the most spectacular grandfather clock here that you’ll definitely want to check out. From there you enter a mirrored room to watch a quick video that shows you all the (unexpected) places you’ll find Waterford Crystal. It is so much more than just fine goblets to drink wine from! Then it’s into the factory where the magic happens.

MOULD ROOM

Waterford Crystal is one of the few companies that continues a practice that is centuries old- the craft of mould making. Made from beech and pear wood for their smoothness and high tolerance to heat, moulds are used by the Master Blowers to shape the molten crystal. Even with their tolerance to heat the moulds only have a life span of about 7-10 days and you can very clearly see the scorch marks on the ones they have on display, some of which were used to create special pieces such as the Saint Patrick’s Day Shamrock Bowl for President Barack Obama.

BLOWING DEPARTMENT

Definitely one of our favourite parts of the tour the Blowing Department has heat, noise, and lots of activity. Starting with the furnaces that reach 1300 °C to turn the crystal into molten red-hot blobs, to the Master Blowers who turn those blobs into elegant shapes right before your eyes. They are focused and meticulous as they work and you likely could stand there all day watching them. You have to wonder if the Master Blowers ever get tired of folks coming by all day staring at them in fascination.

As the crystal cools you watch it turn from orange to clear- but even clear it must still be really hot if the looks of the mitts they use to hold it with are anything to go by!

WASHING & QUALITY INSPECTION

Next up the pieces have the caps removed that held them to the blowpipe, they are ground until the rough edges are removed, and then washed.

The crystal is then inspected (one of six inspections each piece will be put through) and if it isn’t up to Waterford’s impeccable standards it is rejected, smashed, and sent back to the furnace to be melted again.

HAND MARKING

Next up is the hand marking area where each piece has a temporary grid marked on it to assist the Master Cutters when they cut the pattern. The grid is horizontal and vertical guidelines using markers that get removed at a later stage in another round of cleaning.

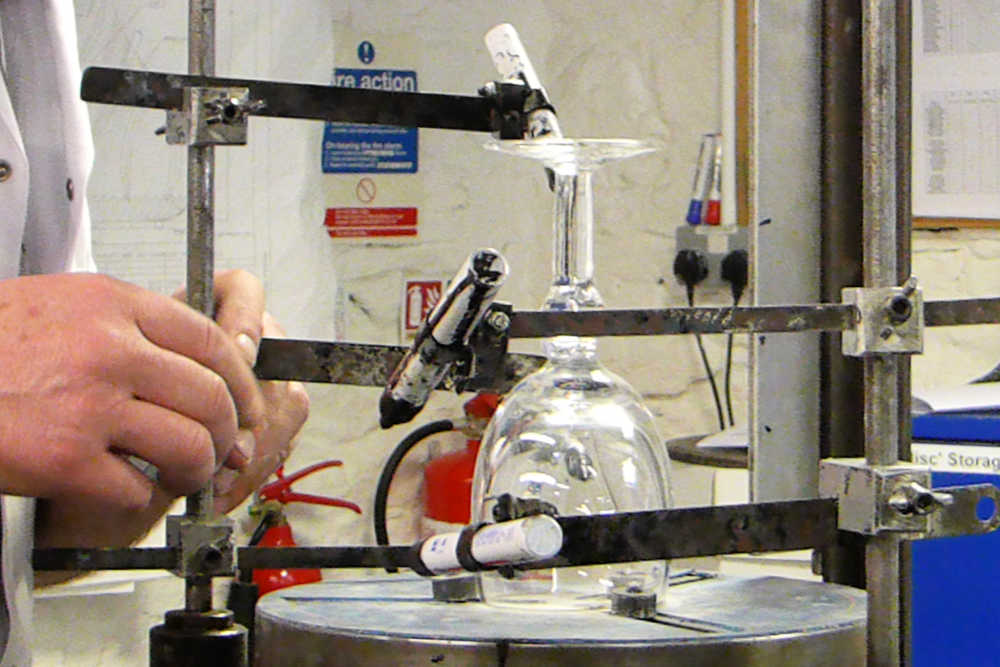

We watched this gentleman at work for quite a few minutes as he would make one line, then make slight adjustments to each of the arms holding a marker, then another line, and another minute adjustment and so on. Each piece could take several minutes to mark (like this water goblet) to possibly hours with some of the very intricate and detailed custom pieces.

CUTTING DEPARTMENT

Each pattern that was drawn on in the hand marking area will have been learned and memorized by the cutter in his training years – which is a minimum of eight years! The Master Cutters learn two types of cutting- Wedge Cutting and Flat Cutting. They rely on their training and skills to judge how much pressure is needed to get the cut right; too much pressure and they’ll cut right through to the other side. Some very intricate pieces are now cut by diamond-tipped wheels controlled by computers to allow for even more precision.

Other pieces are actually sculpted, much like stone is except with a wheel instead of mallets and chisels. In this process, the Master Sculptor creates a 3D piece from a solid block of crystal. These pieces can take up to months to create and, not surprisingly, can cost thousands to tens of thousands of dollars. There are some beautiful examples on display along the tour- just be careful not to bump into one of the tables holding them! How disastrous would that be?

ENGRAVING

The final department on the tour is at the engraving area where a technique called “Intaglio”, which means reverse, is used. The deeper the engraving the more prominent the object appears. This is used on many of the international sporting trophies and limited edition pieces that Waterford creates – many such examples can be seen on the tables along this area.

SHOWROOM

At this point, the tour concludes and you find yourselves back in the original building where you started, but this time at the back of the retail store. And what a beautiful store it is, especially if you are a fan of crystal. You could browse for ages in here looking at all their different designs, special pieces, and for me – tree ornaments. But oh my, some of the prices. After having been on the tour you can easily see why the pieces are as expensive as they are. They are so detailed, hand-cut, and kept to standards of perfection.

PLAN YOUR VISIT TO WATERFORD CRYSTAL

Information last updated December 2019

HOW TO GET THERE

Waterford Crystal can be found at 28 The Mall, Waterford, Ireland.

Buses which stop right by the factory are 360, 360A, 609, w3 and w5.

Parking is available less than five-minutes walk away at Manvers Street Car Park. Parking is €1 per hour.

HELPFUL LINK:

- If you need an app that will navigate you around whether walking, driving or using public transport and even works offline then click for a guide about how to use Here WeGo.

OPENING HOURS

Opening hours vary throughout the year, but the core hours are 0930-1515, opening at 0900 and closing at 1615 at the earliest/latest through the year. The factory is closed between 21st December and 1st January, St Patrick’s Day (17th March) and the last Monday in October. The factory is closed at weekends from November to February. For full opening times please check here.

As all of the attraction is indoors, any time of year is a good time to visit. The tour takes about 50 minutes.

HOW TO BUY TICKETS & SAVE MONEY ON ADMISSION

Basic admission prices are £14.50 for adults, £6.50 for children 10-18 years, £11.50 for students and £12.50 for over 65s. Family tickets for 2 adults and 2 children are £38. One carer per disabled visitor can visit for free.

You can save 10% on adult tickets by purchasing online in advance.

ACCESSIBILITY

The Waterford Crystal Tour is wheelchair accessible.

IS THE WATERFORD CRYSTAL TOUR WORTH THE VISIT?

To witness up close the amazing work and skill that goes into making these ornate pieces of crystal make this tour a great thing to do in Ireland. The guided tour is excellent and you get to see every step of the process of making Waterford Crystal with the expert craftsmen working just feet away from you.

See what others think of this attraction on Trip Advisor.

ADD TO YOUR IRELAND ITINERARY

Céad míle fáilte… a hundred thousand welcomes is something you’ll see plenty in Ireland. And it’s true, visit the Emerald Isle for its history, rugged coastline and friendly people.

- Hook Lighthouse is the oldest operational lighthouse in the world. A lighthouse has stood on the site for over 800 years!

- The reputed site of the conversion of King Aenghus by St Patrick, the Rock of Cashel offers visitors centuries of history and intrigue to explore.

- Experience what life would have been like for emigrants crossing from Ireland to the New World to escape the famine at the Dunbrody Famine Ship Experience.

- A three-walled castle wouldn’t offer much defence to attackers. Learn what happened to the missing fourth wall at Kilkenny Castle.

Want to save this for later? Click the Pinterest button on the left for a pinnable image!

RESOURCES | PLAN YOUR TRIP TO IRELAND

To book flights, rental cars, accommodations, and activities for your trip, please check out our recommended travel providers, favourite apps and websites.

These are a few tours we would recommend for your trip to Ireland.

Some of the links in the post above are affiliate links. This means if you click on the link and purchase the item, we will receive an affiliate commission but this does not affect the price to you. Please read our full disclosure policy here.